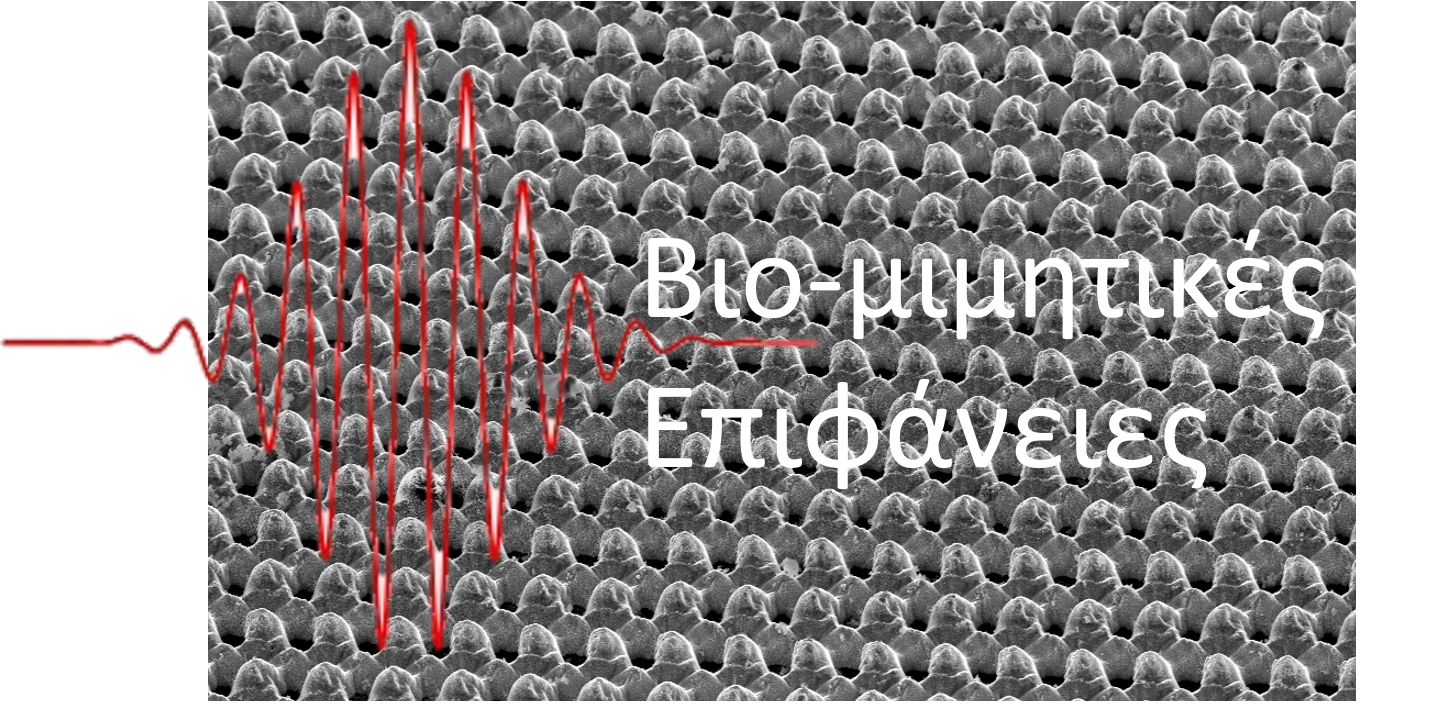

In the Ultrafast Laser Micro- and Nano- processing group (ULMNP) of IESL research is focused on the development of novel ultrafast pulsed laser processing schemes for controlled biomimetic structuring at micro- and nano- scales of a variety of materials, including biopolymers. By applying ultrafast laser pulses novel surface structures with sub-micron sized features are produced while the physical properties of semiconductor, dielectric and metallic surfaces are significantly modified. The biomimetic surfaces developed exhibit controlled dual-scale morphology, that mimics the hierarchical structuring of natural surfaces with exciting properties (i.e. the Lotus leaf, the Shark Skin, the Butterfly wings). As a result, the biomimetic morphology attained gives rise to notable multifunctional properties including water repellence, self-cleaning, antibacterial, anti-sticking, anti-fogging, anti-reflection and combination of those (b) smart, i.e show the ability to change their functionality in response to different external stimuli. The ability to tailor the morphology and chemistry is an important advantage for the use of the biomimetic structures as models to study the dependence of growth, division and differentiation of cells on the surface energy of the culture substrat, as well as 3D scaffolds for tissue regeneration. At the same time, novel ultrafast non-linear imaging tools are employed to characterise the biological processes taking place during the development of tissue into 3D scaffolds. At the same time, ULMNP focuses on the ultrafast laser-based development of various types of nanomaterials, nanolayers and processes applied in photovoltaic, gas sensing and energy storage applications. The exploitation of ultrashort pulses for the doping, functionalization, spectroscopic diagnosis and quality control of graphene and other 2D materials is additionally explored, placing emphasis on the understanding of the fundamental physical properties of such materials.

Research Topics

Ultrafast Laser Processing of Materials

Activities-challenges: Bio-inspired surface modification and functionalization of solid surfaces via ultrashort laser pulses in various types of materials (i.e. semiconductors, metals, dielectrics, polymers), investigation of surface micro/nano structure role on wetting, optical, and tribological applications. Control of surface morphology with shaped ultrashort double pulses. Development of laser induced metasurfaces and investigation of the physical mechanisms that lead to laser induced surface structure formation.

Biomimetic laser processing

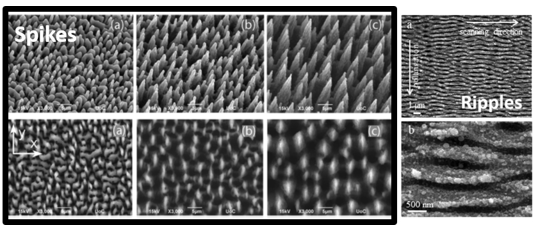

Wetting properties: By applying ultrashort UV, VIS and IR laser pulses novel surface structures with sub-micron sized features are produced while the physical properties of semiconductor, dielectric and metallic surfaces are significantly modified. Developed methods include laser micro/nano surface structuring performed in different media, direct laser writing with variable laser polarization states and combination of those. Further control over the surface topology is achieved by proper functionalization of the 3D structures obtained with well-defined nanostructures. The artificial surfaces developed by processing under ambient controlled gaseous environments or in ambient environment exhibit controlled dual-scale roughness, that mimics the complexity of hierarchical morphology of natural surfaces with exciting wetting properties (i.e. the Lotus leaf, Texas horned Lizard), comprising micro-conical structures decorated with nanometer sized protrusions. The biomimetic morphology attained gives rise to notable wetting properties when combined with methods of tailoring the surface chemistry.

Figure 1: Wetting response and SEM pictures of actual lotus leaf (left) and fs treated silicon (right) surfaces

Optical properties Based on the concepts and underlying principles discovered in nature, an interdisciplinary field has been developed, aiming to design and fabricate photonic biomimetic structures. This capability comes as the outcome of the optimal combination of the ultrafast laser field and material properties that enable the production of features with sizes beyond the diffraction limit (i.e., nanoscale) that can mimic the functionalities of cicada and butterfly wings. A prominent example is the formation of self‐organized subwavelength, laser‐induced periodic surface structures (LIPSS), which have been proven an important asset for the fabrication of nanostructures with a plethora of geometrical features. With precise ultrafast laser processing we can produced high anti-reflective artificial glass surfaces and high absorbing metal and semiconductor materials [1].

Figure 2: SEM images of actual cicada Cretensis wing (left) and of an fs treated glass surface (right). Photograph of half treated glass SiO2 with reduced light reflection (below).

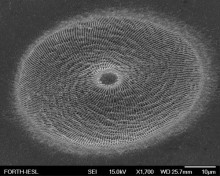

Tribological properties: A prominent aspect of the fs laser material interaction is that the spatial features of the surface structures attained are strongly correlated with the laser beam polarization. However, to date, laser fabrication of biomimetic structures has been demonstrated using laser beams with a Gaussian intensity spatial profile and spatially homogeneous linear polarization. In this context and based on the sensitivity of laser induced structures on laser polarization, it is possible to further advance the complexity of the fabricated structures via utilizing laser beams with a spatially inhomogeneous state of polarization. Therefore we can mimic the skin of elasmobranches like shark for in water drag reduction and reduced friction sliding friction under the presence of oil lubricance [2,3].

Figure 3: SEM images of actual shark skin (left) and of an fs treated metal surface (right)

Controlling 2D LIPSS formation with double pulses

Figure 4: SEM images of 2D structures induced by double pulses on stainless steel surface.

Employing DPI enables us to intervene into the evolution of the structure formation in a non-deterministic way. The interpulse delay (Δτ) is considered the main parameter in DPI, since it defines the stage of structure formation process, which is targeted by the second pulse. Depending on the Δτ value several effects have been observed on 2D LIPSS formation on stainless steel (4). When 1 ps < Δτ < 10 ps the hierarchical morphology of triangular 2D-LIPSS was tailored via tuning the high spatial frequency LIPSS (HSFL) formation (Figure 4, left). At Δτ = 20 ps 2D-HSFL were obtained and a structure morphology inversion was observed (Figure 4, center). When Δτ ranges in the nanosecond timeframe the microfluidic motion of the melt reaches its maximum amplitude. Then the second pulse intervenes to the existing temperature profile and impacts Marangoni flow. We showed that at Δτ = 0.5 ns a variety of 2D subwavelength structures were obtained (Figure 4, right), assuming the development of convection flow (CF) on the surface. According to CF theory the pattern formation apart from the amplitude and temporal profile of the excitation depends on the excitation profile, i.e. the spot profile in the case of laser irradiation (Process I). Therefore, by means of DPI we can manipulate the CF dynamics, while upon tuning of the spot profile we could define the CF pattern that will be developed.

Investigation of LIPSS formation on pre-patterned surfaces

To illustrate the role of pre-patterrned surfaces and impact of laser polarisation in the periodic pattern formation,

Figure 5a: Laser-induced ripples on a pre-patterned surface. A comparison of non-irradiated pre-pattern structures and laser-induced ripples (upper and lower SEM micrographs respectively).

Figure 5b: Electromagnetic modes that are excited which are used to explain the LIPSS formation on prepatterned surfaces.

Nickel surfaces are irradiated with femtosecond laser pulses of polarisation perpendicular or parallel to the orientation of the pre-pattern ridges. The LIPSS formation on pre-patterned surfaces aims to reveal more information regarding to the physical information of the ripples formation induced by ultrashort laser pulses. The detailed analysis of the LIPSS formation in different conditions and ridge distances can set the basis for control of the parameters to fabricate patterns with desired properties for a wide range of optoelectronic applications. To understand the LIPSS formation on prepatterned surfaces a theoretical model has been developed that discusses how the induced electromagnetic modes can account for the orientation and periodicity of the periodic structures [6].

Ultrafast laser induced metasurfaces

Metasurfaces are two-dimensional metamaterials with planar and ultrathin nanostructures that have shown exceptional abilities in light manipulation and versatility in optical applications. The core research strategy here is to exploit ultrafast laser fabrication technology combined with the state-of-the art planar metamaterial designs in order to engineer the geometric parameters of artificially constructed subwavelength meta-atoms and, thus generate a variety of metasurfaces that will enable the manipulation of optical waves in a prescribed manner.

Figure 6: Planar and ultrathin nanostructures fabricated by ultrafast laser processing of silicon

Complex structure generation with advanced spatiotemporal femtosecond beam shaping

Α novel approach for tailoring the laser induced surface topography upon femtosecond (fs) pulsed laser irradiation is followed. The method employs spatially controlled double fs laser pulses to actively regulate the hydrodynamic microfluidic motion of the melted layer that gives rise to the structures formation. The pulse train used, in particular, consists of a previously unexplored spatiotemporal intensity combination including one pulse with Gaussian and another with periodically modulated intensity distribution created by Direct Laser Interference Patterning (DLIP). The interpulse delay is appropriately chosen to reveal the contribution of the microfluidic melt flow, while it is found that the sequence of the Gaussian and DLIP pulses remarkably influences the surface profile attained (Figure 7).

Figure 7: A Gaussian and a DLIP pulse are combined in DLIP irradiation. The delay between the double pulses is 500 ps. After repetitive irradiation a variety of complex morphologies were obtained.

Figure 8: A complex morphology comprising structures in multiple length scales

Apart from the order of the pulses and the shape of the DLIP pulse, tailoring of secondary process parameters impact the induce morphology. After studying the effects of the fluence and the number of irradiations, distinct complex morphologies were obtained comprising features in multiple length scales. An example of such a surface is presented in Figure 8 and analyzed in components of different size by means of inversed furrier transformation [4,5].

Fabrication of Biomimetic 2D Nanostructures through Irradiation of Stainless Steel Surfaces with Double Femtosecond Pulses

Femtosecond laser induced changes on the topography of stainless steel with double pulses is investigated to reveal the role of parameters such as the fluence, the energy dose and the interpulse delay on the features of the produced patterns. Our results indicate that short pulse separation (Δτ = 5 ps) favors the formation of 2D Low Spatially Frequency Laser Induced Periodic Surface Structures (LSFL) while longer interpulse delays (Δτ = 20 ps) lead to 2D High Spatially Frequency LIPSS (HSFL). The detailed investigation is complemented with an analysis of the produced surface patterns and characterization of their wetting and cell-adhesion properties. A correlation between the surface roughness and the contact angle is presented which confirms that topographies of variable roughness and complexity exhibit different wetting properties. Furthermore, our analysis indicates that patterns with different spatial characteristics demonstrate variable cell adhesion response which suggests that the methodology can be used as a strategy towards the fabrication of tailored surfaces for the development of functional implants (Figure 9) [7].

Figure 9: Impact of topography produced with double pulses on stainless steel on (a) wetting and (b) cell adhesion properties.

Tailoring surface topographies on solids with Mid-IR femtosecond laser pulses

Irradiation of solids with ultrashort pulses using laser sources in the mid-infrared (mid-IR) spectral region is a yet predominantly unexplored field that opens broad possibilities for efficient and precise surface texturing for a wide range of applications. In the present work, a detailed combined experimental and theoretical investigation of the impact of laser sources both on the generation of surface modification related effects and patterning on metallic and semiconducting materials is performed. A series of experiments were surface irradiation upon mid-IR ultrafast laser pulses is performed to allow a parametric study and correlate the laser parameters with the onset of material damage and the formation of a variety of periodic surface structures for laser wavelengths λL=3200 nm of pulse duration τp=45 fs. Results for nickel and silicon indicate that the produced topographies comprise high/low spatial frequency laser induced periodic structures similar to those observed at lower wavelengths while groove formation is absent. The evaluation of the damage thresholds entails the incorporation of nonlinear effects generated from three-photon-assisted excitation (for silicon) and the consideration of the role of the non-thermal excited electron population (for nickel) at very short pulse durations. Results demonstrate the potential of surface structuring with mid-IR pulses that can constitute a systematic novel engineering approach with strong fields at long wavelength spectral regions that can be used for advanced industrial laser applications.

Project Members

- Theory

- Dr George.D.Tsibidis (Modelling of laser-matter Interactions)

- Dr Panos Lingos (Electromagnetic Simulatrions)

- Dr Leonidas Mouchliadis (Density Functional Theory calculations)

- Maria-Christina.Velli (Modelling of laser-matter Interactions+Machine learning-based approaches)

- Experiment

- Dr Fotis Fraggelakis (Experiment)

- Dr Stella Maragkaki (Experiment)

- Dr Ioanna Sakelari (Experiment)

- Dr Dimitris Mansour (Experiment)

- Matina Vlahou (Experiment)

- Dr Emmanuel Stratakis (Experiment-Group Leader)

Representative publications

- Papadopoulos A., Skoulas E., Mimidis A., Perrakis G., Kenanakis G., Tsibidis G.D., and Stratakis E., ‘Biomimetic omnidirectional anti-reflective glass via ultrafast laser nanostructuring’, Advanced Materials 31, (32), 1901123 (2019).

- Skoulas E., Manousaki A., Fotakis C, Stratakis E., ‘Biomimetic surface structuring using cylindrical vector femtosecond laser beams’, Scientific Reports 7,1 (2017).

- Stratakis E., Bonse J., Heitz J., Siegel J., Tsibidis G.D., Skoulas E. Papadopoulos A., Mimidis A., Joel A.-C., Comanns P., Kruger J., Florian C., Fuentes-Edfuf Y., Solis J., Baumgartner W., ‘Laser Engineering of Biomimetic Surfaces’ (Review Article), Materials Science and Engineering: R: Reports, 141, 100562 (2020).

- Fraggelakis F., Tsibidis G.D., Stratakis E., ‘Tailoring Sub-micrometer Periodic Surface Structures via Ultrashort Pulsed Direct Laser Interference Patterning’, Physical Review B 103, 054105 (2021).

- Fraggelakis F., Tsibidis G.D., Stratakis E., ‘Ultrashort pulsed laser induced complex surface structures generated by tailoring the melt hydrodynamics’, Opto-Electronic Advances, 5 210052 (2022), (Front Cover of Issue).

- Maragkaki S., Lingos P., Tsibidis G.D., Deligeorgis P., Stratakis E., ‘Impact of pre-patterned structures on features of Laser Induced Periodic Surface Structures’, Molecules 26 (3) 7330 (2021).

- Vlahou M., Fraggelakis F., Manganas P., Tsibidis G.D., Ranella A., and Stratakis E., ‘Fabrication of biomimetic 2D nanostructures through irradiation of stainless steel surfaces with double femtosecond pulses’, , Nanomaterials 12 (4) 623 (2022).

Ultrafast Laser Processing Modelling

Activities-challenges:

- Physical modelling of multiscale processes

- Investigation of surface modification mechanisms in (sub)-ablation and sub-melting conditions in various types of materials (i.e. semiconductors, metals, dielectrics),

- Interpretation of mechanisms that account for Laser Induced Periodic Surface Structures (LIPSS),

- Exploration of carrier dynamics in multilayered materials,

- Role of non-thermal electrons and out-of-equilibrium excited carriers

- Density Functional Theory (DFT)-based calculations of optical properties, excitation conditions, relaxation processes

- Strain propagation and surface modification at different laser polarization states,

- Ultrafast dynamics at mid-IR,

- Modelling Patterning processes through Direct Laser Interference techniques,

- Machine learning based approaches,

- Role of electromagnetic modes in LIPSS formation.

- Surface modification: A desirable effect in the laser-mater processing applications is to control and influence the morphology of the material surface by regulating the way of energy delivery from the laser into the various degrees of freedom of the system. Femtosecond pulsed laser interaction with matter triggers a variety of timescale-dependent processes, influenced by the fluence and pulse duration. A multiscale theoretical investigation is pursued to describe the physical fundamentals and mechanisms that account for the associated experimental observations after single and multiple-pulse ultrashort pulse irradiation and provide a systematic and controllable way of linking the observed surface modification with the applied conditions [1,2,3].

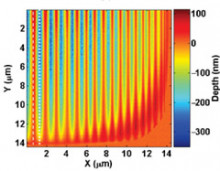

Although surface patterning has been previously investigated upon irradiation with ultrashort pulses in ablation conditions, physics fundamentals of surface modification and a novel surface patterning mechanism for ultrashort pulses have never been addressed in conditions near evaporation (sub-ablation). More specifically, we suggested a new physical mechanism that governs surface patterning formation (i.e. ripples) based on a combination of interference effects (and development of surface plasmon waves) coupled with hydrodynamics capillary induced effects and the dynamics of a superheated liquid layer. The ripple periodicity and morphological changes appear to agree satisfactorily with experimental observations. The model has been revised to allow the description of supra-wavelength structures (grooves) that result from the formation of hydrothermal convection rolls (Fig.1,2). Experimental results supported with theoretical simulations of the underlying physical processes manifest the universality of the mechanisms regardless of the type of the material (Fig.1).

Figure 1: SEM picture, and Simulation results.

Figure 2: (a) hydrothermal waves, (b) convection rolls

- Surface modification for complex polarization states: An extension of the model has been performed to explore the role of laser polarization. More specifically, radial and azimuthal polarisation were considered to elaborate on the effect on the ripple periodicity in various materials (Fig.3 shows subwavelength structure formation in fused silica) [4,5].

Figure 3: Rippled profile with a radially (a,c) and azimuthally (b,d) polarized beam

- Tailoring Sub-micrometer Periodic Surface patterning via Ultrashort Pulsed Direct Laser Interference Patterning (DLIP):

Direct laser Interference Patterning (DLIP) with ultrashort laser pulses (ULP) represents a precise and fast technique to produce tailored periodic sub-micrometer structures on various materials. An experimental and theoretical approach is pursued to investigate the previously unexplored fundamental mechanisms for the formation of unprecedented laser-induced topographies on stainless steel following proper combinations of DLIP with ULP (Figure 4). Special emphasis is given to electron excitation, relaxation processes and hydrodynamical effects that are crucial to the production of complex morphologies. Results are expected to derive new knowledge of laser-matter interaction in combined DLIP and ULP conditions and enable enhanced fabrication capabilities of complex hierarchical sub-micrometer sized structures for a variety of applications. In addition to reveal the impact of the laser beams used and their polarization, two beams are used, one Gaussian and another two- (or four-) beam DLIP of varying polarization (vertical or horizontal). Results indicate that the aforementioned parameters as well as the sequence order of the two pulses play a very important role in the attained topography [6,7].

Figure 4: Patterned profile based on DLIP technique with a two (A) and four (B) laser DLIP beam. Patterned surface is illustrated for single or two delayed pulses. Experimental results are interpreted through simulations.

Figure 5: Patterned profile based on a combination of two delayed (one Gaussian beam and one four beam DLIP) pulses. Experimental results are interpreted through simulations.

- Out-of-equilibrium electron dynamics and impact to mechanical effects: The significant influence of the contribution of the dynamics of produced nonthermalised electrons to electron thermalisation and electron-phonon interaction is also thoroughly investigated within a range of values of the pulse duration. The consideration of the role of the nonthermal electrons in the thermalisation of the lattice leads to thermomechanical changes compared to the results the traditional Two Temperature Model (TTM) provides (Fig.6) [8].

Figure 6: (a) Electronic and lattice temperature profile using the classical TTM and revised TTM, (b) Spatial strain profile simulated TTM and rTTM.

- Out-of-equilibrium electron dynamics: a unification of a DFT approach+ TTM model: To highlight the role of out-of-equilibrium processes for very short pulses a coupling of results from DFTcalculations (evaluation of optical properties) and the classical TTM has been performed to assess the influence of nonthermal electrons in surface damage in 6H-SiC (Fig. 7) [9].

Figure 7: (a) Reflectivity as a function of the photon energy through DFT calculations, (b) coupling of DFT calculations with TTM to compute carrier density evolution for 6H-SiC.

- Ultrafast dynamics and surface modification related effects for mid-IR femtosecond pulses: A detailed theoretical framework was also presented to describes both the ultrafast dynamics and thermal response following irradiation of Silicon [10]/fused silica [11] with ultrashort pulsed lasers in the mid-IR range (Fig.8,9). Results for Silicon demonstrated that the Kerr effect is important at lower wavelengths (~2.2 μm) while it leads to substantially large deviations to the maximum lattice temperature reached that it affects the damage threshold. A systematic analysis of the Surface Plasmon dispersion relation for mid-IR revealed that irradiation in the mid-IR region yielded SP that are weakly confined on the surface, exhibit longer lifetimes, and propagate on larger areas. These features can be potentially exploited to promote mid-IR-based technology to produce sensors, detectors or to present new capabilities in laser-based manufacturing.

Figure 8: Irradiation of Silicon with mid-IR femtosecond pulses

A multiscale modelling approach is performed that correlates conditions for formation of perpendicular or parallel to the laser polarisation low spatial frequency periodic surface structures for low and high intensity mid-IR pulses (not previously explored in dielectrics at those wavelengths), respectively. Results demonstrate a remarkable domination of tunneling effects in the photoionisation rate and a strong influence of impact ionisation for long laser wavelengths. The methodology presented in this work is aimed to shed light on the fundamental mechanisms in a previously unexplored spectral area and allow a systematic novel surface engineering with strong mid-IR fields for advanced industrial laser applications.

Figure 9: Irradiation of Fused SilIica with mid-IR femtosecond pulses

- Machine learning-based approaches: Recently, a new activity has been initiated in which machine learning based approaches and predictive modelling are followed to reduce the number of simulated and real experiments towards determining the laser parameters required to pattern surfaces with morphological features (i.e. ripples, grooves, spikes) required to provide desired functionalities an properties (i.e. antireflective, antifouling, antimicrobial, wetting, etc.) (Fig.10). Simulated data based on physics modelling (Fig.9a) and experimental data (Fig.10b) were used to automate and forecast the effect of laser processing on material structures. The focus is centered on the performance of representative statistical and machine learning algorithms in predicting the outcome of laser processing on a range of materials. Results on experimental data showed that predictive models were able to satisfactorily learn the mapping between the laser’s input variables and the observed material structure. These results are further integrated with simulation data aiming to elucidate the multiscale physical processes upon laser–material interaction. As a consequence, we augmented the adjusted simulated data to the experiment and substantially improved the predictive performance due to the availability of an increased number of sampling points. In parallel, an information-theoretic metric, which identifies and quantifies the regions with high predictive uncertainty, is presented, revealing that high uncertainty occurs around the transition boundaries. Our results can set the basis for a systematic methodology toward reducing material design, testing, and production cost via the replacement of expensive trial-and-error based manufacturing procedures with a precise pre-fabrication predictive tool [12].

Figure 10: (a) Simulated data based on physics modelling, (b) experimental data, (c-d) Machine learning based approaches results. Stainless steel is used as a test material.

- Prepatterned surfaces: The efficiency of light coupling to surface plasmon polariton (SPP) represents a very important issue in plasmonics and laser fabrication of topographies in various solids. To illustrate the role of pre-patterrned surfaces and impact of laser polsarisation in the excitation of electromagnetic modes and periodic pattern formation, Nickel surfaces are irradiated with femtosecond laser pulses of polarisation perpendicular or parallel to the orientation of the pre-pattern ridges. Experimental results indicate that for polarisation parallel to the ridges, laser induced periodic surface structures (LIPSS) are formed perpendicularly to the pre-pattern with a frequency that is independent of the distance between the ridges and periodicities close to the wavelength of the excited SPP. These results are also predicted from simulations (Fig.11). By contrast, for polarisation perpendicular to the pre-pattern, the periodicities of the LIPSS are closely correlated to the distance between the ridges for pre-pattern distance larger than the laser wavelength. The experimental observations are also interpreted through a multi-scale physical model in which the impact of the interference of the electromagnetic modes is revealed (Figure 12).

Figure 11 . Topography following irradiation of Nickel with fifteen laser pulses at 1026 nm (a) Upper view, (b) Side view.Polarisation is along the Y-axis.

Figure 12: . Spatial profile of the energy distribution for one, two, three pulses. The fourth figure illustrates the final topography (side view)

The pre-pattern periods and wavelengths studied here are (a-d) Λ=700nm with λ=513nm, (e-h) Λ=1400nm with λ=513nm, (i-l) Λ=1300nm with λ=1026nm, (m-p) Λ=1900nm with λ=1026nm. As seen from the above pre-pattern configurations, for Λ nearly as twice as the laser wavelength in (d-h) and (m-p), the electromagnetic intensity is accumulated on four locations within the pre-pattern valley. Electromagnetic modes restricted between the pre-pattern ridges produce temperature elevations and production of melt while the temperature gradients induce movement of the melting. Thus two hills emerge inside the pre-pattern valley with periodicity ~Λ/4 apart. Similarly for Λ comparable to the laser wavelength (a-d) and (i-l) the electromagnetic energy is accumulated on two regions within the pre-pattern valley which in turn melt material movement and re-solidification produce one hill in the middle of the valley forming Λ/2 periodicity. For Λ periodicities nearly less than the laser wavelength. The above numerical results confirm the LIPSS periodicity dependence on then pre-pattern period in good agreement with experimental results.

- Damage threshold evaluation and optical parameters in thin films: The employment of femtosecond pulsed lasers has received significant attention due to its capability to facilitate fabrication of precise patterns at the micro- and nano- lengths scales. A key issue for efficient material processing is the accurate determination of the damage threshold that is associated with the laser peak fluence at which minimal damage occurs on the surface of the irradiated solid. Despite a wealth of previous reports that focused on the evaluation of the laser conditions that lead to the onset of damage, the investigation of both the optical and thermal response of thin films of sizes comparable to the optical penetration depth is still an unexplored area. In this report, a detailed theoretical analysis of the impact of various parameters such as the photon energies and material thickness on the damage threshold for various metals (Au, Ag, Cu, Al, Ni, Ti, Cr, Stainless Steel) is investigated (Figure 13). A multiscale physical model is used that correlates the energy absorption, electron excitation, relaxation processes and minimal surface modification which leads to the onset of material damage. The satisfactory agreement of the theoretical model with some experimental results indicates that the damage threshold evaluation method could represent a systematic approach towards designing efficient laser-based fabrication systems and optimizing the processing outcome for various applications [13].

Figure 13: Reflectivity (left column), Absorbance (middle column) and damage threshold evaluation (right column) following irradiation of Al, Ni, Cr with fs laser pulses of two different photon energies (λL=515 nm and λL=1026 nm).

j. The synergy of electromagnetic effects and thermophysical properties of metals in the formation of laser induced periodic surface structures: Femtosecond pulsed lasers have been widely used over the past decades for precise materials structuring at the micro- and nano- scales. In order, though, to realize efficient material processing and account for the formation of laser induced periodic surfaces structures (LIPSS), it is very important to understand the fundamental laser-matter interaction processes. Significant contribution to the LIPSS profile appears to originate both from the electromagnetic fingerprint of the laser source and the thermal response of the material. In this work, we follow a systematic, step-by-step approach to predict the formation of LIPSS on metals due to the development of a spatially periodic energy deposition that results from the interference of electromagnetic far fields on a non-flat surface profile. We also demonstrate that the electromagnetic effects, alone, are not sufficient to allow the LIPSS formation, therefore, we emphasize on the crucial role of electron diffusion and electron-phonon coupling on the formation of stable periodic structures. Gold and stainless Steel are considered as two materials to test the theoretical model while simulation results appear to confirm the experimental results that, unlike gold, fabrication of pronounced LIPSS on stainless Steel is feasible (Figure 14) [14].

Figure 14: Absorbed energy distributions on the transverse plane for Au (a) and SS (b) surfaces. (c), (d) illustrate the Fourier transform of (a), (b), respectively. The green circles represent the boundary of ![]() where stands for the wave-vector of light propagation in air (double headed arrow indicates laser polarization direction). (e) and (f) illustrate normalized Z-component of the electric field at the propagation plane XZ. (double-headed arrows indicates laser polarization direction). In this cross section, two nano-holes are located at positions X=-2540 nm and X=1630 nm. The white line represents the air-metal interface.

where stands for the wave-vector of light propagation in air (double headed arrow indicates laser polarization direction). (e) and (f) illustrate normalized Z-component of the electric field at the propagation plane XZ. (double-headed arrows indicates laser polarization direction). In this cross section, two nano-holes are located at positions X=-2540 nm and X=1630 nm. The white line represents the air-metal interface.

Project Members

- Theory

- Dr George.D.Tsibidis (Modelling of laser-matter Interactions)

- Dr Panos Lingos (Electromagnetic Simulations)

- Dr Leonidas Mouchliadis (Density Functional Theory calculations)

- Maria-Christina.Velli (Modelling of laser-matter Interactions+Machine learning-based approaches)

- Experiment

- Dr Fotis Fraggelakis (Experiment)

- Dr Stella Maragkaki (Experiment)

- Dr Ioanna Sakelari (Experiment)

- Dr Dimitris Mansour (Experiment)

- Matina Vlahou (Experiment)

- Dr Emmanuel Stratakis (Experiment-Group Leader)

Representative publications

- Tsibidis G.D., Barberoglou M., Loukakos P.A., Stratakis E., and Fotakis C. (2012) ‘Dynamics of ripple formation on silicon surfaces by ultrashort laser pulses in subablation conditions’, Physical Review B, 86, 115316.

- Tsibidis G.D., Skoulas E., A.Papadopoulos, and Stratakis E. (2016), ‘Convection roll-driven generation of supra-wavelength periodic surface structures on dielectrics upon irradiation with femtosecond pulsed lasers’, Physical Review B (Rapid Communications) 94, 081305.

- Tsibidis G.D., Fotakis C., and Stratakis E. (2015), ‘From ripples to spikes: a hydro-dynamical physical mechanism to interpret femtosecond laser induced self-assembled structures’, Physical Review B (Rapid Communications), 92 ,041405.

- Tsibidis G.D., Skoulas E., and Stratakis E. (2015) “Ripple formation on Nickel irradiated with radially polarized femtosecond beams’, Optics Letters, 40 (22), 5172.

- Papadopoulos A., Skoulas E., Tsibidis G.D, and Emmanuel Stratakis E., ‘Formation of periodic surface structures on dielectrics after irradiation with laser beams of spatially variant polarisation: a comparative study’, Applied Physics A 124, 146 (2018).

- Fraggelakis F., Tsibidis G.D., Stratakis E., ‘Tailoring Sub-micrometer Periodic Surface Structures via Ultrashort Pulsed Direct Laser Interference Patterning’, Physical Review B 103, 054105 (2021).

- Fraggelakis F., Tsibidis G.D., Stratakis E., ‘Ultrashort pulsed laser induced complex surface structures generated by tailoring the melt hydrodynamics’, Opto-Electronic Advances, 5 210052 (2022), (Front Cover of Issue).

- Tsibidis G.D. (2018), ‘Ultrafast dynamics of non-equilibrium electrons and strain generation under femtosecond laser irradiation of Nickel’, Applied Physics A, 124,311.

- Mouchliadis L., Pedio M., Stratakis E., ‘Modelling ultrafast out-of-equilibrium carrier dynamics and relaxation processes upon irradiation of hexagonal Silicon-Carbide with Tsibidis G.D., femtosecond laser pulses’, Physical Review B 101, 075207 (2020).

- Petrakakis E., Tsibidis G.D., and Stratakis E., ‘Modelling of the ultrafast dynamics and surface plasmon properties of silicon upon irradiation with mid-IR femtosecond laser pulses’, Physical Review B 99, 195201 (2019).

- Tsibidis G.D., Stratakis E., ‘Ionization processes and laser induced periodic surface structures in dielectrics with mid-infrared femtosecond laser pulses’ Scientific Reports 10, 8675 (2020).

- Velli MC, Tsibidis G.D., Mimidis A., Skoulas E., Pantazis Y., Stratakis E., ‘Predictive modeling approaches in laser-based material processing’, Journal of Applied Physics, 28 183102 (2020).

- Tsibidis GD, Mansour D., Stratakis E., ‘Damage threshold evaluation of thin metallic films exposed to femtosecond laser pulses: the role of material thickness’ (submitted arXiv:2205.05342).

- Tsibidis GD, Lingos P., Stratakis E., ‘The synergy of electromagnetic effects and thermophysical properties of metals in the formation of laser induced periodic surface structures’ (submitted arXiv:2206.02351).

Direct Laser Fabrication of Biomimetic, 3D Scaffolds for Tissue Regeneration

Short Description and Main Findings of the Research Topics:

Research Topic 1: Direct Laser Micro/Nano Fabrication of Biomimetic Scaffolds

Short description

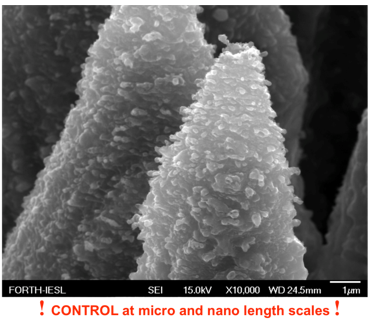

The aim is to investigate the biocompatibility of laser-engineered biomimetic 3D scaffolds fabricated on hard metallic and soft polymeric materials, exhibiting different micro/nano topographies and surface energies.

Abstract

The extracellular matrix provides the necessary cues at micro and nano-scale for cell adhesion, alignment, proliferation and differentiation. In this context, the surface topography of biomaterials can have an important impact on cellular adhesion, growth and proliferation. Apart from the overall roughness, the detailed morphological features, at all length scales, significantly affect the cell-biomaterial interactions in a plethora of applications including structural implants, tissue engineering scaffolds and biosensors.

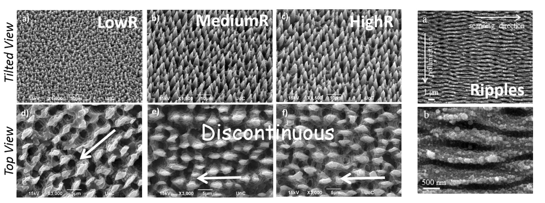

The main objective is to investigate the biocompatibility of laser-engineered biomimetic 3D scaffolds fabricated on hard metallic and soft polymeric materials, exhibiting different micro/nano topographies and surface energies. Ultrafast pulsed laser irradiation is considered as a simple, precise and effective microfabrication method to produce structures of controlled geometry and pattern regularity. The variation of irradiation parameters, such as fluence and irradiation environment gives rise to significant changes of the surface morphology attained (i.e. geometry, dimensions and density of the structures). As a consequence, morphologies ranging from microcones to nanoripples (Figure 1), as well as hierarchical micro/nano structures (Figure 2) can be fabricated and further used as cell culture platforms.

The laser fabricated scaffolds with controlled surface roughness, wettability and surface energy can be used as model platforms to study the influence of topography on cell response. It is demonstrated that, depending on the laser processing conditions, distinct cell-philic or cell-repellant patterned areas can be attained with a desired motif (Figure 3). Laser processing could thus enable spatial patterning of cells in a controllable manner, giving rise to advanced capabilities in cell biology research.

Research has shown that cell adhesion and migration could be tuned via the laser-patterned substrates. It was also shown that microconical substrates could influence sympathetic and sensory neuronal alignment as well as NGF-induced PC12 cell differentiation (see also Research Topic 2).

Scaffolds on hard materials

Figure 1: Various types of femtosecond laser fabricated scaffolds on hard materials with feature sizes ranging from a few hundreds of nanometers to tens of microns (C Simitzi, P Efstathopoulos, A Kourgiantaki, A Ranella, I Charalampopoulos, C Fotakis, I Athanassakis, E Stratakis, A Gravanis, Biomaterials, 2015, 67: 115-128, doi.org/10.1016/j.biomaterials.2015.07.008).

Figure 2: Laser fabricated arrays of biomimetic hierarchical micro/nano conical structures(Chara Simitzi, Pascal Harimech, Syrago Spanou, Christina Lanara, Amelie Heuer-Jungemann, Aleka Manousaki, Costas Fotakis, Anthi Ranella, Antonios G Kanaras, Emmanuel Stratakis, Biomater. Sci., 2018,6,1469, doi: 10.1039/c7bm00904f)

Figure 3: Patterning of Schwann (SW10) cells cultured on laser fabricated substrates exhibiting cell-philic and cell-repellant areas (Ch Yiannakou, Ch Simitzi, A Manousaki, C Fotakis, A Ranella, E Stratakis, 2017 Biofabrication 9 025024, https://doi.org/10.1088/1758-5090/aa71c6)

Scaffolds on soft materials

a) Replicated Scaffolds

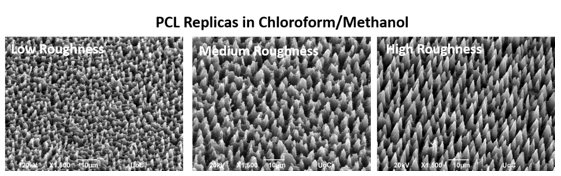

Soft lithography has been successfully used to transfer well-defined micro-sized patterns from hard materials to soft (bio)materials. The replication of micro/nano topographies is realised on polymeric systems, such as poly (lactic-co-glycolic acid) (PLGA), polycaprolactone (PCL) (Figure 4) and polydimethylsiloxane (PDMS), in order to investigate the effect of material surface energy and stiffness on cellular responses (adhesion, proliferation, survival, growth and differentiation).

Figure 4a: SEM images (tilted view) of PLGA replicas with the hierarchical (microcone-spikes and nano-ripples) topographies (Babaliari, E., Kavatzikidou, P., Angelaki, D., Chaniotaki, L., Manousaki, A., Siakouli-Galanopoulou, A., Ranella, A., & Stratakis, E. (2018). Engineering Cell Adhesion and Orientation via Ultrafast Laser Fabricated Microstructured Substrates. International journal of molecular sciences, 19(7), 2053, doi: 10.3390/ijms19072053).

Figure 4b: SEM images (tilted view) of PCL replicas exhibiting various microcone topographies.

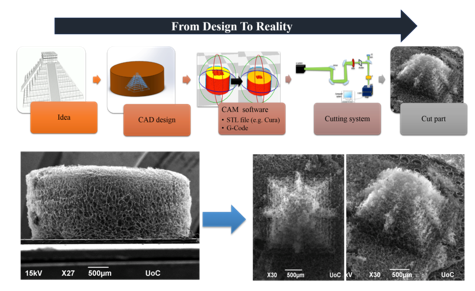

b) 3D scaffolds of porous collagen via subtractive laser manufacturing:

Laser micromachining provides a novel CAD/CAM rapid prototyping microfabrication process that can provide complex implant designs based on an established biomaterial utilized in clinical practice. It is shown that fs laser micromachining of porous collagen (Figure 5), in particular, can fabricate high-precision micron-sized features (e.g. canals, wells) and provides novel ways to modulate the microenvironment felt by interacting cells, tailor implants to the needs of individual patients, or tools to meet the current major challenges of regenerative medicine.

Figure 5: fs laser micromachining of porous collagen scaffolds

Research Topic 2: 3D Scaffolds Hosting Neurons and Neural Stem Cells

Short Description

The aim is to develop laser-engineered micro/nano scaffolds (3DLS) for hosting 3D cultures of neural stem cells.

Abstract

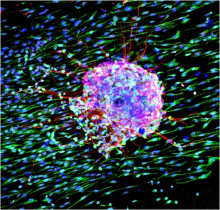

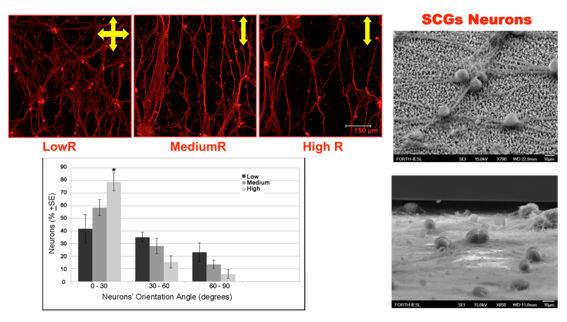

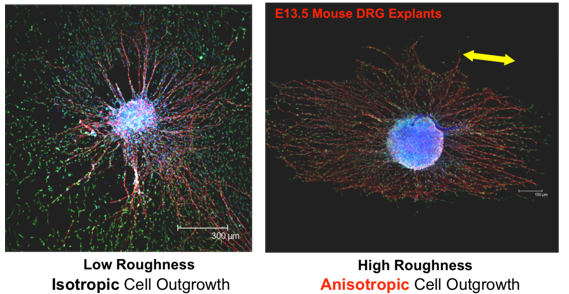

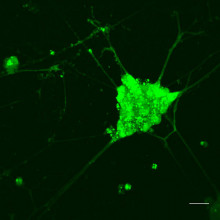

Neural stem cells (NSCs) are intrinsically capable of differentiating into different neural cell types: neurons, oligodendrocytes and astrocytes, and have emerged as important players in the generation and maintenance of neural tissue as well as in treating neurodegenerative diseases and neurological injuries. However, successful development of NSC-based therapies requires more sophisticated technologies from the ones that are already available and deeper understanding of NSCs’ functions. The NSCs reside in a complex three-dimensional (3D) niche in vivo where they are exposed to a plethora of signals, including physical signals such as tensile, compressive and shear stresses, discontinuities and differences in roughness of the ECM molecules. Topography is capable of inducing different effects on NSCs, such as changes in cell morphology, alignment (Figures 1 and 2), adhesion, migration, proliferation, cytoskeleton organization and also differentiation (Figure 3). However, simulating this 3D environment for NSC culture and subsequent development of 3D neuronal networks that maintain functional neuronal properties (synaptogenesis and neurotrophic performance) remains a challenge.

To respond to this challenge we have fabricated 3D laser-engineered micro/nano scaffolds (3DLS) featuring different micro/nano topographies for hosting neurons, glia and NSCs. These are advantageous platforms to study the biology of NSC proliferation, differentiation, neuritogenesis and synaptogenesis. Patterning of neuronal outgrowth in vitro is important in tissue engineering as well as for the development of neuronal interfaces with desirable characteristics. Laser-patterned biomimetic scaffolds could potentially be a useful platform for patterning neurons into artificial networks, allowing the study of neuronal cells interactions under 3D ex-vivo conditions.

Figure 1: SCGs neurons orientation on laser fabricated discontinuous anisotropic microconical substrates (C Simitzi, P Efstathopoulos, A Kourgiantaki, A Ranella, I Charalampopoulos, C Fotakis, I Athanassakis, E Stratakis, A Gravanis, Biomaterials, 2015, 67: 115-128, doi.org/10.1016/j.biomaterials.2015.07.008).

Figure 2: DRG cultures on laser fabricated discontinuous anisotropic microconical substrates (C Simitzi, P Efstathopoulos, A Kourgiantaki, A Ranella, I Charalampopoulos, C Fotakis, I Athanassakis, E Stratakis, A Gravanis, Biomaterials, 2015, 67: 115-128, doi.org/10.1016/j.biomaterials.2015.07.008).

Figure 3: Effect of surface roughness on PC12 cell differentiation. (C. Simitzi, E. Stratakis, C. Fotakis, I. Athanassakis and A. Ranella, Microconical silicon structures influence NGF-induced PC12 cell morphology, J Tissue Eng Regen Med2015;9: 424–434, DOI:10.1002/term.1853)

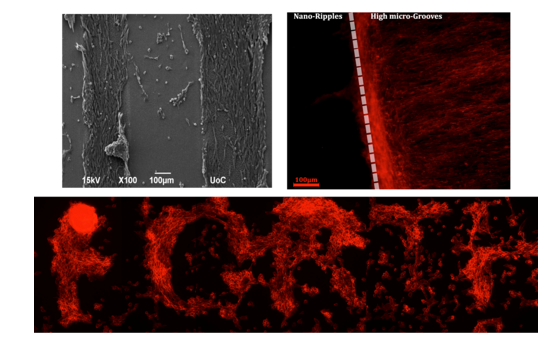

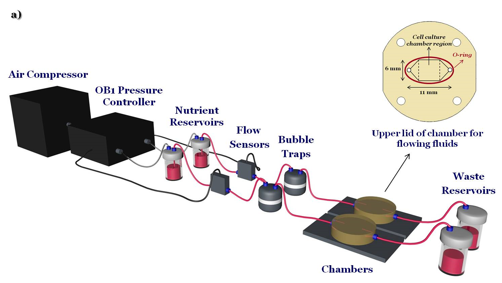

Research Topic 3: Development of microfluidic systems for cell studies under dynamic culture conditions

Understanding the cell-biomaterial interaction under dynamic culture conditions, in vitro, is potentially useful in the fields of tissue engineering and regenerative medicine.

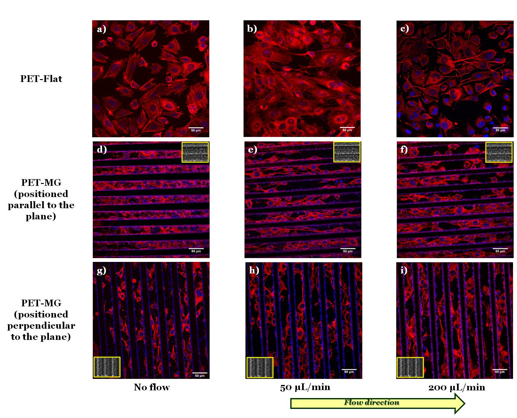

A precise flow controlled microfluidic system with specific custom-designed chambers, incorporating laser-microstructured polyethylene terephthalate (PET) substrates comprising microgrooves, is developed to assess the combined effect of shear stress and topography on cells’ behavior (Fig.1). Specifically the dynamic cultures are performed for the study of the cytoskeleton, directionality and proliferation of cells on micro-nano patterns. A comparison between static and dynamic cultures is always performed in combination with computational flow simulations to calculate accurately the shear stress values. The main findings demonstrate that wall shear stress gradients may be acting either synergistic or antagonistic depending on the substrates groove orientation relative to the flow direction (Fig.2, Fig.3).

Figure 1: Custom-designed Microfluidic System

Figure 2: Confocal images of SW10 cells cultured on the PET-Flat (a, b, c) or inside the MG of the PET-MG substrates (d-i), under static (a, d, g) or dynamic conditions, applying 200 (c, f, i) μL/min, on the third day of culture. The cytoskeleton of the cells is visualized with red color (Alexa Fluor® 680 Phalloidin) while the nuclei with blue color (DAPI). The direction of the flow was parallel (f) or perpendicular (i) to the microgrooves. The inset SEM images, framed by a yellow box, depict the geometry of microgrooves (paper under submission).

Figure 3: Directional polar plots of cells’ cytoskeleton: a) No flow, PET-Flat (black line) 200 μL/min, PET-Flat (blue line), b) No flow, PET-MG (green line) - 200 μL/min parallel to MG, PET-MG (turquoise line), c) No flow, PET-MG (green line) - 200 μL/min perpendicular to MG, PET-MG (dark blue line). The black and red arrows represent the direction of the flow and the microgrooves, respectively.

Moreover, an additional microfluidic chamber incorporating polymeric microgrooved substrates that could be inserted to a non-linear microscope for live imaging observation is developed for nanotoxicology studies. The effect of nanoparticles on cells is examined in terms of survival and proliferation both under static and dynamic conditions (Fig.4).

Figure 4: Observation of live NIH 3T3 cells cultured on PDMS flat and microgrooved substrates with ZnO NPs inside the microfluidic chamber, under static conditions, with the NLO microscope. Scale bar: 10 μm.

In collaboration with Mary Kefalogianni and Dr. Sotiris Psilodimitrakopoulos

Selected Publications:

-

C. Simitzi, E. Stratakis, C. Fotakis, I. Athanassakis and A. Ranella, J Tissue Eng Regen Med, 2015;9: 424–434, DOI:10.1002/term.1853

-

Ch Yiannakou, Ch Simitzi, A Manousaki, C Fotakis, A Ranella, E Stratakis, 2017 Biofabrication 9 025024, doi: 10.1088/1758-5090/aa71c6

-

C. Simitzi, A. Ranella, E. Stratakis, Acta Biomaterialia, Volume 51, 15 March 2017, Pages 21-52, doi: 10.1016/j.actbio.2017.01.023.

-

Chara Simitzi, Pascal Harimech, Syrago Spanou, Christina Lanara, Amelie Heuer-Jungemann, Aleka Manousaki, Costas Fotakis, Anthi Ranella, Antonios G Kanaras, Emmanuel Stratakis, Biomater. Sci., 2018,6,1469, doi: 10.1039/c7bm00904f

-

Babaliari, E., Kavatzikidou, P., Angelaki, D., Chaniotaki, L., Manousaki, A., Siakouli-Galanopoulou, A., Ranella, A., & Stratakis, E. (2018). International journal of molecular sciences, 19(7), 2053, doi: 10.3390/ijms19072053

Main research expertise of the LaBio team:

Main medical applications: neural implants, bone implants, corneal implants, drug delivery etc

Project Members:

Alumni of the Subgroup

In collaboration with the following members:

• Dr. Sotiris Psilodimitrakopoulos

• Dr. Athanasia Kostopoulou

2D Materials

Abstract:

The research topic aims at the Investigation and Engineering of the optoelectronic properties of two-dimensional (2D) materials.

Two-dimensional Transition Metal Dichalcogenides MX2 (M=Mo, W and X=S, Se, Te) are of keen interest for emerging optoelectronic and valleytronic applications. The main activities in our lab focus on the optical response of 2D layered materials and their heterostructures. Spectroscopic techniques such as μ-PL, μ-Reflectance, and Raman are used to characterize the samples from 4K to 300K. We investigate how the degree of valley polarization (VP)-under resonant and non-resonant conditions-is affected by the dielectric environment in different heterostructures such as MX2/h-BN, MX2/Graphene, as well as their corresponding encapsulated structures. Besides, a fast-photochemical doping technique was developed in our lab to sufficiently control the carrier density of a single MX2 layer by incorporating chlorine atoms on the surface. Photochlorination leads to a controllable modification of VP that is directly related to the total number of the active defect sites and consequently to the control of the non-radiative exciton lifetime. We also study the PL emission and VP of suspended MX2 in different configurations with respect to strain induced by patterned substrates. Suspended MX2 monolayers (near zero strain) display enhanced PL and absorption due to the absence of charged excitons.

Spectroscopy of 2D materials provide the principal knowledge towards the development of state-of-the-art optoelectronic and valleytronic devices.

Research topics:

- Fabrication of Graphene and other 2D materials

- Spectroscopy of 2D materials and their heterostructures

- Photochemical doping of Graphene and other 2D materials

- Optoelectronic properties of TMDs at different dielectric environments

- Transient Absorption Spectroscopy of 2D materials

Highlights:

- Spatially selective reversible charge carrier density tuning in WS2 monolayers via photochlorination

- Tunable charge carrier concentration of chlorine doped 1L-WS2

- The effect can be reversed upon continuous wave laser scanning of the monolayer in air

(a) Schematic representation of the process used for the photochlorination of TMDs. (b) Evolution of the Raman Spectra of WS2 monolayer with the photochlorination time shown in the inset; evolution of the out-of-plane vibrational mode A’1 (c) Evolution of the PL spectra of a 1L-WS2 at 78 K, with the photochlorination time. Evolution of the calculated electron density with the photochlorination time and the ratio of normalized intensities of the X and X− peaks as a function of the photochlorination time. (d) Reversal of the photochlorination effect upon CW laser rastering of the chlorine-doped area, indicated by the suppresion of the PL emission by the area assigned as C. (e) Electronic band structures of 1L-WS2 with Chlorine atoms filling S vacancies (left panel), with Chlorine atoms adsorbed on the basal plane (right panel).

I.Demeridou, I. Paradisanos, Yuanyue Liu, N. Pliatsikas, P. Patsalas, S. Germanis, N. T. Pelekanos,

W.A. Goddard III, G. Kioseoglou and E. Stratakis, 2D Materials 6.1 (2018): 015003.

- Tuning the valley polarization in WS2 monolayers with photochemical doping

- Controlled valley polarization via modifying the electron densities in the crystal lattice of chlorine doped 1L-

- Reduction of circular polarization is directly related to the increase of the non-radiative exciton lifetime (τNR) - Elimination of the defect sites in the crystal lattice

(a) Optical image of WS2/hBN (b) PL spectra at 4K excited with 543nm laser for different photochlorination times analyzed for σ+ (red) and σ- (blue) helicity. (c) Circular polarization as function of the photochlorination time at T=4K. (d) Temperature dependence of the circular polarization for the neutral exciton for the pristine sample (black points) and for photochlorination times 4s (red) and 20s (blue). (e) Transient Absorption spectra of the A-exciton for the photochlorinated WS2 (black) and the as-prepared WS2 (red) at 78K.

I.Demeridou, A. Papadopoulos, G. Kourmoulakis, L. Mouchliadis, E. Stratakis, & G. Kioseoglou, Applied Physics Letters 118.12 (2021): 123103.

- Prominent room temperature valley polarization in WS2/Graphene heterostructures grown by chemical vapor deposition

- The degree of valley polarization of WS2 is considerably influenced by the material type used to form the heterostructure.

- The interaction between WS2 and Graphene has a strong effect on the temperature dependent depolarization

- The observed low depolarization rate in the WS2/Gr heterostructure is attributed to the nearly temperature independent scattering rate

- Significant variations in the degree of polarization are also observed at 4K between the different heterostructure configurations

(a) Optical images of hBN/WS2/hBN and (b) WS2/Gr. (c) and (d) T-dependent valley polarization for X0 of hBN/WS2/hBN and WS2/Gr under 543 and 594 nm excitation, respectively.

I.Paradisanos, K. M. McCreary, D. Adinehloo, L. Mouchliadis, J. T. Robinson, Hsun-Jen Chuang, A. T. Hanbicki, V. Perebeinos, B. T. Jonker, E. Stratakis, and G. Kioseoglou, Applied Physics Letters 116.20 (2020): 203102.

- Room temperature observation of biexcitons in exfoliated WS2 monolayers

- We report on the existence of biexcitons in mechanically exfoliated WS2 flakes from 78K up to room temperature

- Performing temperature and power dependent PL measurements, we identify the biexciton emission channel through the superlinear behavior of the integrated PL intensity as a function of the excitation power density

- Neutral and charged excitons show a linear to sublinear dependence in the whole temperature range. From the energy difference between the emission channels of the biexciton and neutral exciton, a biexciton binding energy of 65–70meV is determined

(a) Temperature-dependent PL spectra under 3.8kW/cm2 excitation power density. (b) Integrated PL intensity of L, XX/D, X-, and X peaks for different excitation densities. The XX/D peak exhibits a superlinear relationship with a power law exponent of 1.4 for excitation densities higher than ~1 kW/cm2. (c) 3D plot showing the emission strength of the XX/D at different excitation densities, at 78K. With increasing the excitation power density the biexciton emission dominates the spectra.

I.Paradisanos, S. Germanis, N. T. Pelekanos, C. Fotakis, E. Kymakis, G. Kioseoglou, and E. Stratakis,

Applied Physics Letters 110.19 (2017): 193102.

- Spatial Non-Uniformity in Exfoliated WS2 Single Layers

- Spatial variation of exciton complexes across the surface of monolayers

- Neutral excitons and trions competition due to the presence of oxygen species

(a) Typical optical microscopy image of exfoliated WS2 flakes. (b) Fluorescence image of WS2 monolayer. The stronger PL emission originates from the edges, creating a “donut” effect. (c) Intensity profile across the flake, following the line scan of Fig. 1b. (d) PL spectra comparison of two different spots on the flake (inset of Figure 1d). The PL emission from the central area is dominated by charged exciton (trion) recombination (X–, at 1.97eV) while the emission from the edges is mainly due to the neutral excitons (X0 at 2.01eV).

I.Paradisanos, N. Pliatsikas, P. Patsalas, C. Fotakis, E. Kymakis, G. Kioseoglou and E. Stratakis, Nanoscale 8.36 (2016): 16197.

6.Suspended and Strained areas on a single monolayer WS2flake

- Realization of a control method to create suspended and strained areas on a single flake

- Full spectroscopic characterization (Raman, PL, Spin-Valley polarization and Reflectivity) is utilized to study the system

- Neutral excitons dominate the photoluminescence from the suspended areas in combination with decreased spin-valley polarization, attributed to reduced carrier density

- Towards realization and fabrication of multifunctional devices utilizing a single TMD layer

Collaborators

- Vasili Perebeinos, Department of Electrical Engineering, SUNY at Buffalo NY, USA

- Aubrey Hanbicki, Laboratory for Physical Sciences, University of Maryland, USA

- Kathleen M. McCreary, Naval Research Laboratory, USA

- John Parthenios, Principal Staff Scientist, FORTH/ICE-HT, Greece

- Konstantinos Papagelis, Department of Physics, Aristotle University of Thessaloniki, Greece

- Panos Patsalas, Department of Physics, Aristotle University of Thessaloniki, Greece

- Joe Christodoulides, Naval Research Laboratory, Washington, D.C

Publications

- Tuning the valley polarization in WS2 monolayers via control of active defect sites induced by photochemical doping

I.Demeridou, A. Papadopoulos, G. Kourmoulakis, L. Mouchliadis, E. Stratakis, & G. Kioseoglou, Applied Physics Letters 118.12 (2021): 123103.

- Prominent room temperature valley polarization in WS2/Graphene heterostructures grown by chemical vapor deposition

I.Paradisanos, K. M. McCreary, D. Adinehloo, L. Mouchliadis, J. T. Robinson, Hsun-Jen Chuang, A. T. Hanbicki, V. Perebeinos, B. T. Jonker, E. Stratakis, and G. Kioseoglou, Applied Physics Letters 116.20 (2020): 203102.

- Spatially selective reversible charge carrier density tuning in WS2 monolayers via photochlorination

I.Demeridou, I. Paradisanos, Yuanyue Liu, N. Pliatsikas, P. Patsalas, S. Germanis, N. T. Pelekanos,

W.A. Goddard III, G. Kioseoglou and E. Stratakis, 2D Materials 6.1 (2018): 015003.

- Room temperature observation of biexcitons in exfoliated WS2 monolayers

I.Paradisanos, S. Germanis, N. T. Pelekanos, C. Fotakis, E. Kymakis, G. Kioseoglou, and E. Stratakis,

Applied Physics Letters 110.19 (2017): 193102.

- Spatial Non-Uniformity in Exfoliated WS2 Single Layers

I.Paradisanos, N. Pliatsikas, P. Patsalas, C. Fotakis, E. Kymakis, G. Kioseoglou and E. Stratakis, Nanoscale 8.36 (2016): 16197.

- Intense Femtosecond Photoexcitation of bulk and monolayer MoS2

I.Paradisanos, E. Kymakis, C. Fotakis, G. Kioseoglou, and E. Stratakis, Appl. Phys. Lett., 105 (2014), 041108.

Project Members

Prof. George Kioseoglou & Dr. Emmanuel Stratakis

Dr. Sotiris Psilodimitrakopoulos

Dr. Leonidas Mouchliadis

Dr. Ioanna Demeridou

Mr. Antonis Papadopoulos

Mr. George Kourmoulakis

Ms. Eirini Katsipoulaki

Mr. George Maragkakis

Dr. Ioannis Paradisanos (Alumni)

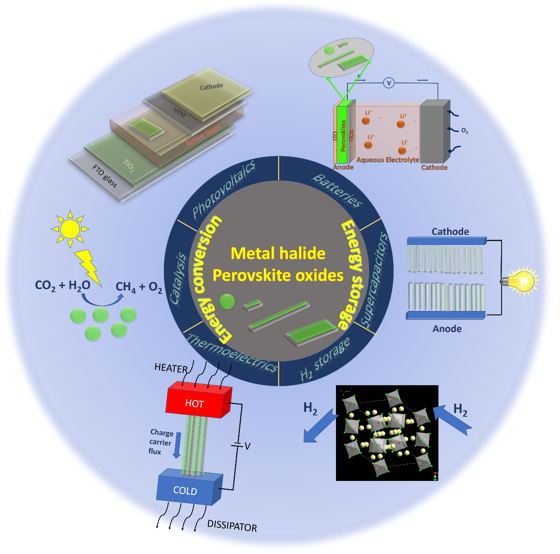

Objective: The objective of this activity is the application of ultrafast laser time-resolved spectroscopy in the fields of photovoltaics, thermoelectric polymers, and plasmonic photocatalysts towards optimizing materials performance and expanding their applications.

Abstract: In Photovoltaics: Femtosecond time-resolved Transient Absorption Spectroscopy (TAS) is used for studying the fundamental photo-physics and decay dynamics in organic photovoltaics (OPVs) and perovskite solar cells (PSCs). Namely, TAS provides important insights on the charge carrier dynamics such as electron-hole injection times and exciton recombination rates that are well known to be directly correlated with the performance of the devices. Figure 1a presents a schematic representation of TAS experimental setup, while Figure 1b depicts a typical optical density (ΔOD) spectrum of a glass/ITO/PEDOT:PSS/CH3NH3PbI3 architecture as a function of wavelength and time from which the charge carrier dynamics are revealed upon following fitting analysis. Notably, the TAS setup in ULMNP Laboratory allows the performance of measurements under dry ambient, as well as, in-situ probing at variable temperatures. This part of the research activity is implemented by a joint effort between the ULMNP Group and the Nanomaterials and Organic Electronics Group of the Center of Materials Technology and Photonics (CEMATEP) of the Hellenic Mediterranean University (HMU), headed by Prof. Emmanuel Kymakis. Our continuous mission is to provide research facilities for state-of-the-art research in the multidisciplinary field of nanotechnology and advanced electronics. In brief the activity focuses on the following:

- Exploring the effect of hole transport layer on the charge transfer, carrier trapping and hole injection dynamics within PSCs.

- In-situ monitoring of the charge carrier dynamics of CH3NH3PbI3 perovskite during crystallization process.

- Transient photo-induced bleaching relaxation dynamics in OPVs.

- Correlation of charge carrier transport dynamics with electrical measurements towards enhancing device performance and stability.

Figure 1: (a) Schematic representation of TAS experimental setup. (b) Optical density (ΔOD) transient absorption spectra of a glass/ITO/PEDOT:PSS/CH3NH3PbI3 architecture.

In Thermoelectric Polymers: Along similar lines, the application of TAS technique is expanded to thermoelectric composite polypropylene-based polymers that contain carbon nanotubes (CNTs). The latter are responsible for generating electrical current upon exposure to temperature differentials. Recent data from our Laboratory reveal that TAS is powerful technique and a figure-of-merit method to explore ultrafast phenomena and relaxation processes that take place within these CNT composite polymers, and thus, providing important information for the design and development of novel configurations with enhanced thermoelectric performance (Figure 2). The characterization of thermoelectric polymers by means of TAS are implemented within the frame of the European project InComEss. Overall, the activity targets the following:

- Correlating exciton dynamics of single and hybrid CNT composite polymers with thermoelectric performance, towards the design of advanced energy scavenging devices.

Figure 2: Correlation of exciton dynamics and lifetimes with the thermoelectric performance of polypropylene-based polymer composites containing various types of carbon nanotubes (CNTs).

In Plasmonic Photocatalysts: The key objective of employing TAS in plasmonic photocatalysts such as CuFeS2 arises from the challenge to shed light on the mechanism of their catalytic action. It was found recently that CuFeS2 nanoparticles exhibit remarkable catalytic performance in terms of selectivity, speed, yield, and recyclability when it comes to the reduction of nitroarenes into the corresponding amines. This chemical process is of enormous importance in the field of chemical industry for the cost-effective production of polymers, pharmaceuticals, agrochemicals, and dyes. As revealed by TAS the success of the CuFeS2 nanoparticles relies on the generation of hot electrons and heat in both conduction and intermediate bands, while having suitable energy band gap with hydrazine (Figure 3). The research outcome of this activity was published in Nature Nanotechnology and with respect to TAS it focuses on:

- Insights into the mechanism of action of CuFeS2 catalyst for nitroarenes reduction.

Figure 3: (a) EDS chemical mapping of CuFeS2 nanoparticles. (b) Schematic representation of energy level diagrams of CuFeS2 catalyst and hydrazine. (c) Time-resolved transient absorption spectra of the CuFeS2 catalyst showing the optical density difference (ΔOD) as a function of wavelength at various time delays, along with the corresponding transient dynamics.

Active projects: InComEss, LASERGRAPH.

Contact persons: Dr. Ioannis Konidakis, Dr. Emmanuel Stratakis.

Project members: Dr. Ioannis Konidakis, Dr. Emmanuel Stratakis.

Project members Alumni: Prof. Costas Fotakis, Dr. Kyriaki Savva, Dr. Efthymis Serpetzoglou.

Collaborators: Prof. Emmanuel Kymakis (HMU), Dr. Petra Pötschke (IPF-Dresden), Dr. Aristides Bakandritsos (UPOL).

Selected publications:

1. “Fast and selective reduction of nitroarenes under visible light with an earth‑abundant plasmonic photocatalyst”, A.C. Poulose, G. Zoppellaro, I. Konidakis, E. Serpetzoglou, E. Stratakis, O. Tomanec, M. Beller, A. Bakandritsos and R. Zbořil, Nat. Nanotechnol. 17, 485 (2022).

2. “Charge carrier dynamics in different crystal phases of CH3NH3PbI3 perovskite photovoltaic active layer”, E. Serpetzoglou, I. Konidakis, G. Kourmoulakis, I. Demeridou, K. Chatzimanolis, C. Zervos, G. Kioseoglou, E. Kymakis and E. Stratakis, Opto-Electron. Sci. 1, 210005 (2022).

3. “Nitrogen-doped carbon nanotube/polypropylene composites with negative Seebeck coefficient”, B. Krause, I. Konidakis, M. Arjmand, U. Sandararaj, R. Fuge, M. Liebscher, S. Hampel, M. Klaus, E. Serpetzoglou, E. Stratakis and P. Pötschke, J. Compos. Sci. 4, 14 (2020).

4. “In situ monitoring of the charge carrier dynamics of CH3NH3PbI3 perovskite crystallization process”, E. Serpetzoglou, I. Konidakis, T. Maksudov, A. Panagiotopoulos, E. Kymakis and E. Stratakis, J. Mater. Chem. C 7, 12170 (2019).

5. Limitations of a polymer-based hole transporting layer for application in planar inverted perovskite solar cells”, M. Petrovic, T. Maksudov, A. Panagiotopoulos, E. Serpetzoglou, I. Konidakis, M.M. Stylianakis, E. Stratakis and E. Kymakis, Nanoscale Adv. 1, 3107 (2019).

6. “Improved charge carrier dynamics of CH3NH3PbI3 perovskite films synthesized by means of laser-assisted crystallization”, I. Konidakis, T. Maksudov, E. Serpetzoglou, G. Kakavelakis, E. Kymakis and E. Stratakis, ACS Appl. Energy Mater. 1, 5101 (2018).

7. “α,β-Unsubstituted meso-positioning thienyl BODIPY: a promising electron deficient building block for the development of near infrared (NIR) p-type donor-acceptor (D-A) conjugated polymers”, B.M. Squeo, V.G. Gregoriou, Y. Han, A. Palma-Cando, S. Allard, E. Serpetzoglou, I. Konidakis, E. Stratakis, A. Avgeropoulos, T.D. Anthopoulos, M. Heeney, U. Scherf and C.L. Chochos, J. Mater. Chem. C 6, 4030 (2018).

8. “Enhancement of the power-conversion efficiency of organic solar cells via unveiling an appropriate rational design strategy in indacenodithiophene-alt-quinoxaline π-conjugated polymers”, C.L. Chochos, R. Singh, V.G. Gregoriou, M. Kim, A. Katsouras, E. Serpetzoglou, I. Konidakis, E. Stratakis, K. Cho and A. Avgeropoulos, ACS Appl. Mater. Interfaces 10, 10236 (2018).

9. “Improved carrier transport in perovskite solar cells probed by femtosecond transient absorption spectroscopy”, E. Serpetzoglou, I. Konidakis, G. Kakavelakis, T. Maksudov, E. Kymakis and E. Stratakis, ACS Appl. Mater. Interfaces 9, 43910 (2017).

10. “The role of chemical structure in indacenodithienothiophene-alt-benzothiadiazole copolymers for high performance organic solar cells with improved photo-stability through minimization of burn-in loss”, C.L. Chochos, N. Leclerc, N. Gasparini, N. Zimmerman, E. Tatsi, A. Katsouras, D. Moschovas, E. Serpetzoglou, I. Konidakis, S. Fall, P. Leveque, T. Heiser, M. Spanos, V.G. Gregoriou, E. Stratakis, T. Ameri, C.J. Brabec and A. Avgeropoulos, J. Mater. Chem. A 5, 25064 (2017).

Applications of Non-Linear Imaging in Materials Science

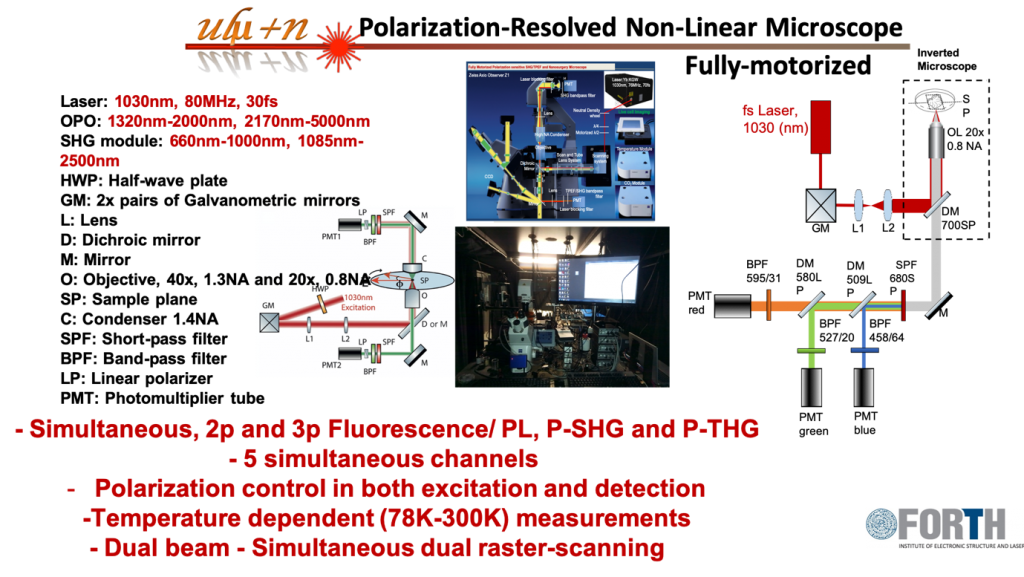

Two-photon photoluminescence (2PL), polarization-resolved second-harmonic generation (P-SHG) and polarization-resolved third-harmonic generation (P-THG) imaging microscopy of non-linear materials.

The goal of the project is to employ 2PL imaging and precise polarization measurements of SHG, and THG signal and interpret the produced signals in order to gain further physical insight into nanomaterials (e.g. the graphene or the graphene related 2D materials).

Contact Person(s):

Dr. Emmanuel Stratakis

Dr. Sotiris Psilodimitrakopoulos

Research Topics

Non-linear optical properties of graphene and graphene related 2D materials

Abstract

Despite their similarities, 2PL, SHG and THG are based on fundamentally different phenomena. 2PL relies on nonlinear multiphoton absorption, followed by fluorescence emission while SHG relies on non-centrosymmetry and nonlinear scattering. Finally, THG originates from changes in the samples’ index of diffraction. The consequences of those basic differences are exploited and utilized in this project as new contrast mechanisms for characterizing nanomaterials of interest, e.g. the graphene and the graphene related 2D materials.

In particular, by varying the polarization angle of the excitation field and recording the second and third harmonic intensity, we are able to produce polar diagrams whose patterns are consequently connected with the crystal orientation, the relative orientation between different layers or even the way in which electrons are distributed among the available energy states of the system. Such a link is made possible through application of nonlinear optics and the derivation of equations for the SHG and THG intensity that are used to fit the experimental data and infer the values of interesting parameters such as the armchair orientation, the twist angle, the valley population imbalance etc.

The continuous interaction between theory and experiment within the Imaging subgroup offers an ideal means for enhancing our insight on the nonlinear phenomena occurring in organic and inorganic systems under intense laser light excitation and allows for both prognostics and diagnostics of 2D materials and biological samples.

Femtosecond laser raster-scanning microscopy imaging is used to study the nonlinear optical properties (second and third harmonic generation) of atomically thin materials.

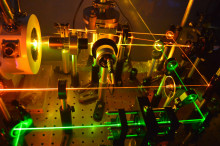

Fully-motorized Polarization-Resolved Non-Linear Microscope

- Simultaneous, 2p and 3p Fluorescence/ PL, P-SHG and P-THG

- 5 simultaneous channels

- Polarization control in both excitation and detection

-Temperature dependent (78K-300K) measurements, using a cryostat at the sample plane

- Dual beam - Simultaneous dual raster-scanning

Experimental Setup

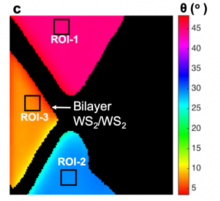

Mapping of the main crystallographic axis and crystal quality diagnostics in transition metal dichalcogenides

Polarization-resolved second harmonic generation (P-SHG) imaging is performed in monolayer transition metal dichalcogenides (TMDs), such as MoS2, WS2, MoSe2 and WSe2, to map the main cystallographic axis (armchair) , and evaluate the crystal quality.

- [“Imaging the crystal orientation of 2D transition metal dichalcogenides using polarization-resolved second-harmonic generation,” G. M. Maragkakis, S. Psilodimitrakopoulos, L. Mouchliadis, I. Paradisanos, A. Lemonis, G. Kioseoglou and E. Stratakis, Opto-Electronic Advances, 2, 190026 (2019).]

Ultra-high resolution Mapping of Armchair orientation

["Ultrahigh-resolution non-linear optical imaging of the armchair orientation in 2D transition metal dichalcogenides,"S. Psilodimitrakopoulos, L. Mouchliadis, I. Paradisanos, A. Lemonis, G. Kioseoglou and E. Stratakis, Light: Science & Applications, 7, 18005 (2018).]

Quantification of Crystal quality

["Ultrahigh-resolution non-linear optical imaging of the armchair orientation in 2D transition metal dichalcogenides,"S. Psilodimitrakopoulos, L. Mouchliadis, I. Paradisanos, A. Lemonis, G. Kioseoglou and E. Stratakis, Light: Science & Applications, 7, 18005 (2018).]

Twist angle mapping

The twist angle (the relative angle between stacked 2D monolayers) is a new degree of freedom in 2D materials, since its affects the physical properties of a multilayer structure. Here, we map the twist angle in TMD-based structures by performing P-SHG imaging and developing suitable SHG interference models.

Twist angle mapping in TMD homobilayers

- “Twist Angle mapping in layered WS2 by Polarization-Resolved Second Harmonic Generation,” S. Psilodimitrakopoulos, L. Mouchliadis, I. Paradisanos, G. Kourmoulakis, A. Lemonis, G. Kioseoglou and E. Stratakis, Scientific Reports, 9, 14285 (2019).]

Real-time twist angle imaging in TMD heterobilayers

- “Real-time spatially resolved determination of twist angle in transition metal dichalcogenide heterobilayers,” S. Psilodimitrakopoulos, L. Mouchliadis, G. M. Maragkakis, G. Kourmoulakis, A. Lemonis, G. Kioseoglou and E. Stratakis, 2D Materials 8, 015015, (2021).]

- “Real-time spatially resolved determination of twist angle in transition metal dichalcogenide heterobilayers,” S. Psilodimitrakopoulos, L. Mouchliadis, G. M. Maragkakis, G. Kourmoulakis, A. Lemonis, G. Kioseoglou and E. Stratakis, 2D Materials 8, 015015, (2021).]

Comparison between optical and electron diffraction imaging of twist-angle in 2D TMD bilayers

[“Optical versus electron diffraction imaging of twist-angle in 2D transition metal dichalcogenide bilayers” S. Psilodimitrakopoulos, A. Orekhov, L. Mouchliadis, D. Jannis, G. M. Maragkakis, G. Kourmoulakis, N. Gauquelin, G. Kioseoglou, J. Verbeeck and E. Stratakis, npj 2D Materials & Applications 5, 77, (2021).]

[“Optical versus electron diffraction imaging of twist-angle in 2D transition metal dichalcogenide bilayers” S. Psilodimitrakopoulos, A. Orekhov, L. Mouchliadis, D. Jannis, G. M. Maragkakis, G. Kourmoulakis, N. Gauquelin, G. Kioseoglou, J. Verbeeck and E. Stratakis, npj 2D Materials & Applications 5, 77, (2021).]

Probing valley population imbalance in TMDs with temperature-dependent SHG imaging

Degenerate minima in the bandstructure of TMDs—valleys—provide an additional degree of freedom that can be used for information transport and storage. When these atomically thin crystals interact with intense laser light, the emerging SHG inherits special characteristics that reflect not only the broken inversion symmetry in real space but also the valley anisotropy in reciprocal space. The temperature-induced change of the SHG intensity dependence on the excitation field polarization is a fingerprint of valley population imbalance in TMDs.

- "Probing valley population imbalance in transition metal dichalcogenides via temperature-dependent second harmonic generation imaging” L. Mouchliadis, S. Psilodimitrakopoulos, G. M. Maragkakis, I. Demeridou, G. Kourmoulakis, A. Lemonis, G. Kioseoglou & E. Stratakis, npj 2D Materials & Applications 5, 6, (2021).]

- "Probing valley population imbalance in transition metal dichalcogenides via temperature-dependent second harmonic generation imaging” L. Mouchliadis, S. Psilodimitrakopoulos, G. M. Maragkakis, I. Demeridou, G. Kourmoulakis, A. Lemonis, G. Kioseoglou & E. Stratakis, npj 2D Materials & Applications 5, 6, (2021).]

- "Probing valley population imbalance in transition metal dichalcogenides via temperature-dependent second harmonic generation imaging” L. Mouchliadis, S. Psilodimitrakopoulos, G. M. Maragkakis, I. Demeridou, G. Kourmoulakis, A. Lemonis, G. Kioseoglou & E. Stratakis, npj 2D Materials & Applications 5, 6, (2021).]

- "Probing valley population imbalance in transition metal dichalcogenides via temperature-dependent second harmonic generation imaging” L. Mouchliadis, S. Psilodimitrakopoulos, G. M. Maragkakis, I. Demeridou, G. Kourmoulakis, A. Lemonis, G. Kioseoglou & E. Stratakis, npj 2D Materials & Applications 5, 6, (2021).]

Third harmonic generation in 2D materials

THG imaging is performed in TMD-based structures in order to obtain complementary to second harmonic generation information about the crystal orientation and homogeneity.

Collaborators

Prof. Johan Verbeeck

Prof. Panos Patsalas

Prof. Andrey Turchanin

Dr. Maria Sygletou

Dr. Ioannis Paradisanos

Publications

- “Optical versus electron diffraction imaging of twist-angle in 2D transition metal dichalcogenide bilayers” S. Psilodimitrakopoulos, A. Orekhov, L. Mouchliadis, D. Jannis, G. M. Maragkakis, G. Kourmoulakis, N. Gauquelin, G. Kioseoglou, J. Verbeeck and E. Stratakis, npj 2D Materials & Applications 5, 77, (2021).

- 2. “Self-assembled dichroic plasmonic nitride nanostructures with broken centrosymmetry for second-harmonic Generation”, D. Babonneau, S. Camelio, G. Abadias, D. Christofilos, I. Arvanitidis, S. Psilodimitrakopoulos, G. M. Maragkakis, E. Stratakis, N. Kalfagiannis, and P. Patsalas,, ACS Applied Nano Materials 4, 9, (2021).

- "Probing valley population imbalance in transition metal dichalcogenides via temperature-dependent second harmonic generation imaging” L. Mouchliadis, S. Psilodimitrakopoulos, G. M. Maragkakis, I. Demeridou, G. Kourmoulakis, A. Lemonis, G. Kioseoglou & E. Stratakis, npj 2D Materials & Applications 5, 6, (2021).

- “Real-time spatially resolved determination of twist angle in transition metal dichalcogenide heterobilayers,” S. Psilodimitrakopoulos, L. Mouchliadis, G. M. Maragkakis, G. Kourmoulakis, A. Lemonis, G. Kioseoglou and E. Stratakis, 2D Materials 8, 015015, (2021).

- “Imaging the crystal orientation of 2D transition metal dichalcogenides using polarization-resolved second-harmonic generation,” G. M. Maragkakis, S. Psilodimitrakopoulos, L. Mouchliadis, I. Paradisanos, A. Lemonis, G. Kioseoglou and E. Stratakis, Opto-Electronic Advances, 2, 190026 (2019).

- “Twist Angle mapping in layered WS2 by Polarization-Resolved Second Harmonic Generation,” S. Psilodimitrakopoulos, L. Mouchliadis, I. Paradisanos, G. Kourmoulakis, A. Lemonis, G. Kioseoglou and E. Stratakis, Scientific Reports, 9, 14285 (2019).

- "Ultrahigh-resolution non-linear optical imaging of the armchair orientation in 2D transition metal dichalcogenides,"S. Psilodimitrakopoulos, L. Mouchliadis, I. Paradisanos, A. Lemonis, G. Kioseoglou and E. Stratakis, Light: Science & Applications, 7, 18005 (2018).