A new scientific study titled “Laser 3D Micro-/Nano-Structurization of Luminescent Materials”, published in Advanced Optical Materials, presents exciting new findings. The research was led by scientists from the Institute of Electronic Structure and Laser (IESL – FORTH), Elmina Kabouraki, and Maria Farsari, in collaboration with Artūr Harnik, Greta Merkininkaitė, Dimitra Ladika, Arūnas Čiburys, Simas Šakirzanovas, and Mangirdas Malinauskas from Vilnius University.

Overview

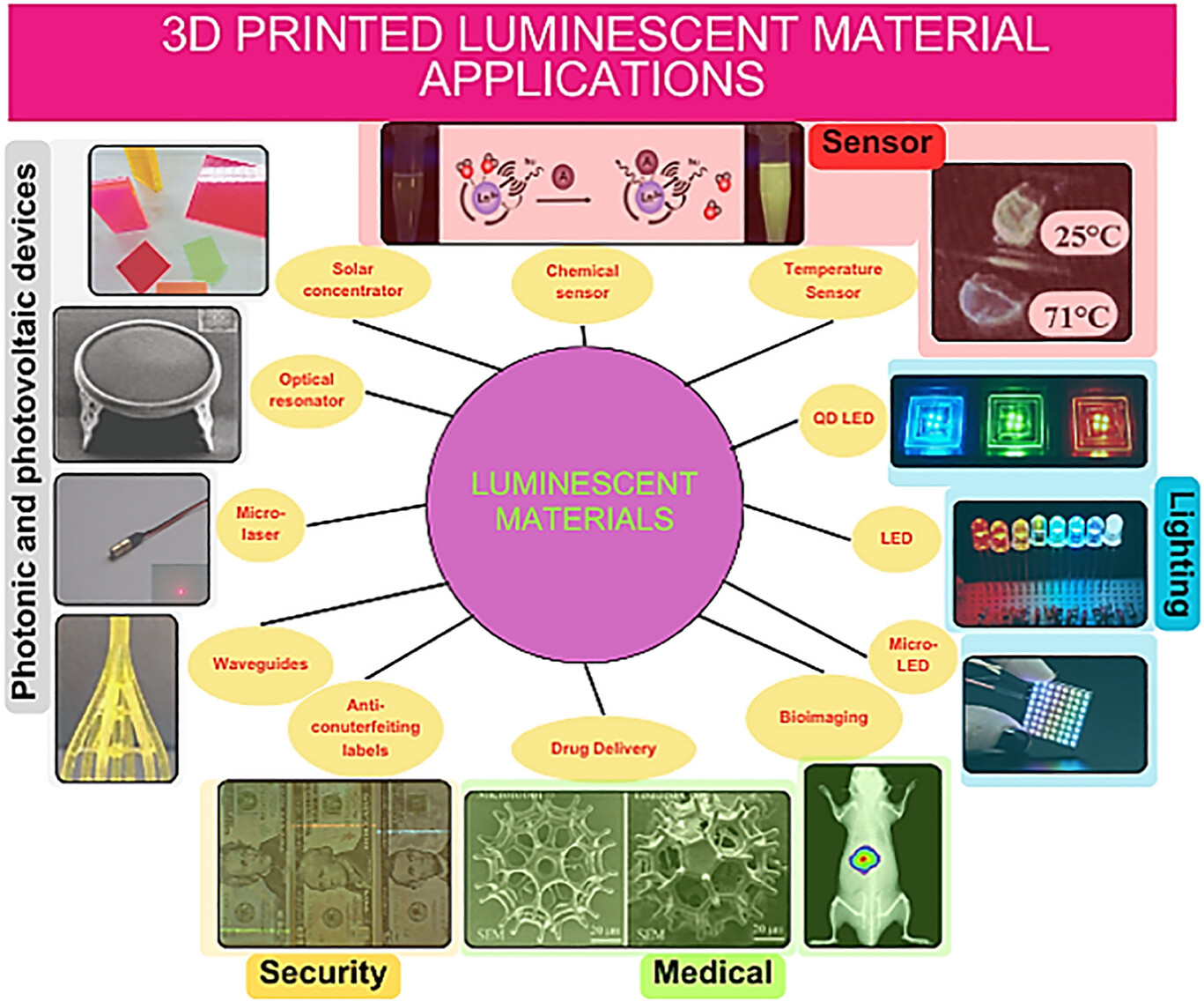

The researchers explored various 3D printing techniques for microstructures, focusing particularly on luminescent materials used in applications like bioimaging, microlasers, and micro-LEDs. They noted that traditional manufacturing methods, such as monocrystal growth, tend to be expensive and time-consuming, often involving extensive post-processing. In contrast, laser direct writing was highlighted for its ability to significantly reduce both production time and costs. This method also enables two-photon polymerization, which improves the quality of 3D-printed structures and allows modification of the phosphors’ emission spectrum, thereby expanding their application range. Additionally, the researchers pointed out that laser writing can sometimes be used as a synthesis technique for new compounds. The review covered different 3D printing approaches, types of materials (organic, hybrid, and inorganic), and the fabrication of luminescent microstructures. It emphasized how laser direct writing and 3D lithography open new possibilities for both altering existing luminescent materials and creating novel ones. Overall, the study aimed to highlight successful 3D printing strategies and their potential outcomes, underscoring the innovative applications enabled by these advancements in luminescent materials.

Reference: Harnik, A. et al. Laser 3D Micro-/Nano-Structurization of Luminescent Materials. Advanced Optical Materials (2025). https://doi.org/10.1002/adom.202500316