News

Conceptualised, developed and constructed in the context of the CALLOS project, TRIENA is a compact, portable, field-ready analytical instrument, fusing three spectrochemical techniques: Laser-Induced Breakdown Spectroscopy, LED-Induced Fluorescence, and Diffuse Reflectance spectroscopy.

In 2025, the Journal of Physics B: Atomic, Molecular and Optical Physics (IOP Publishing) highlighted a selection of outstanding works that shaped atomic and molecular physics during the year. Among these was a review article led by researchers from the Foundation for Research and Technology-Hellas (FORTH), Institute of Electronic Structure and Laser (IESL), underscoring the institute’s leading role in research on strong-field and quantum light–matter interactions.

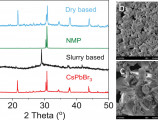

The open access research paper entitled "Processing and Compositional Effects on the Stability of All-Inorganic Metal Halide Perovskite Anodes: A Comparative Study of Dry- vs. Slurry-Fabricated Electrodes," resulting from a collaboration between the Institute of Electronic Structure and Laser (IESL-FORTH), the Democritus University of Thrace (DUTH), and the University of Crete, has been published in the prestigious journal Advanced Materials Technologies (Wiley).