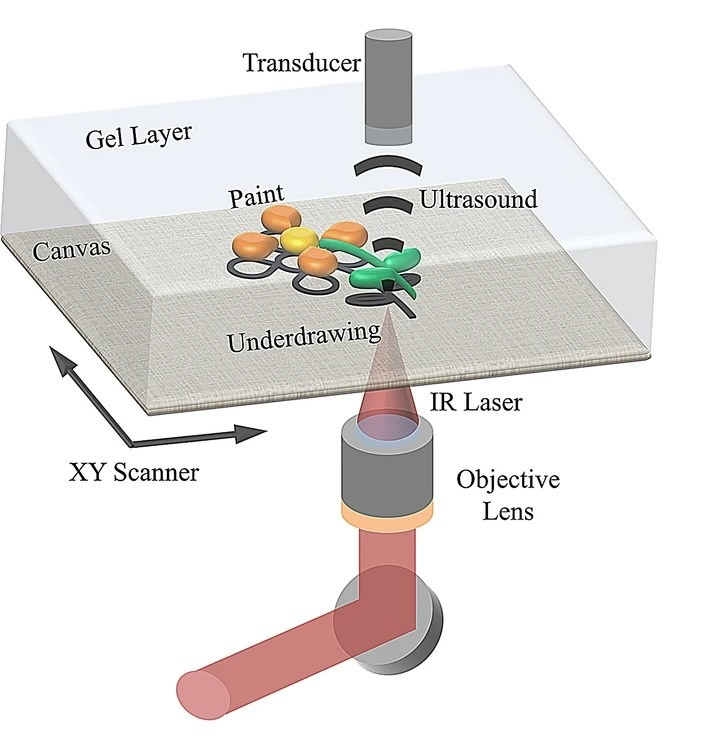

The optimized for CH diagnostic applications photoacoustic (PA) imaging system can reveal well-hidden features in paintings or layered documents and provide structural information of optically opaque layers in artworks [1]. Furthermore, a novel non-contact PA monitoring apparatus can record the intrinsically generated acoustic waves during laser cleaning interventions [2] on stonework or paintings, allowing for precise control of the process.

The non-invasive PA imaging apparatus employs a Q-switched Nd:YAG laser (SL404, Spectron Laser Systems, maximum pulse energy 30 mJ, pulse duration: 10 ns, pulse repetition rate: 10 Hz) emitting near infrared radiation at 1064 nm for the efficient excitation of PA signals. Each sample is firmly fixed on a custom-made holder and irradiated using an adjustable energy fluence to generate PA waves from optically absorbing regions, which are detected in ambient air by a spherically focused non-contact transducer (NCT1-D7-P10, The Ultran Group, nominal central frequency: 1 MHz; focal distance: 10 mm; numerical aperture: 0.31). The signals are subsequently enhanced by a low-noise RF amplifier (62 dB amplification) prior their digitization and recording by an oscilloscope (DSO7034A, Agilent Technologies, bandwidth: 350 MHz). To form an image, the sample is raster scanned along its surface using a set of high precision XY motorized stages, to attain a point-by-point data acquisition in synchronization with the trigger signal of the laser source. The recorded waveforms are processed for high frequency noise elimination before the estimation of the peak-to-peak PA amplitude value, providing the contrast of the final reconstruction.

The PA monitoring apparatus either a contact or an air-coupled ultrasonic transducer for the detection of acoustic waves in the 1-5 MHz regime. Following the incidence of each cleaning pulse, the generated PA signal is digitized and recorded through a high-speed oscilloscope which is synchronized with the laser trigger. Waveforms are processed in real time using custom-developed algorithms to provide multiparametric information on the progress of laser cleaning interventions including the material’s extraction levels, the accurate determination of effective cleaning, as well as, the evaluation of potential side-effects on the substrates.